Mike Silvers, CPRC, Owner, Silvers Systems Inc. and FRSA Technical Director - November 2025

The question above arises from time to time, usually when a building inspector discovers someone installing shingles that have no wrappers or very plain wrappers with little pertinent information on them. The inspector may wonder whether the shingles can be used in Florida and, if so, on what kind of structures.

To understand my answer to the question, we'll start by investigating what the Florida Building Code (FBC) states about building and structure classifications. It’s important to understand that one way the FBC deals with these classifications is through risk categories. These categories refer to the type of occupancy the building will be used for and how many people can occupy it. They also consider the civil importance of the building. The factors that determine the risk category of a building are shown in the Florida Building Code, Building (FBCB), Table 1604.5 Risk Category of Buildings and Other Structures. The table uses four different categories: I, II, III and IV with I being the least important and IV being the most important. You can see this in the table on the next page.

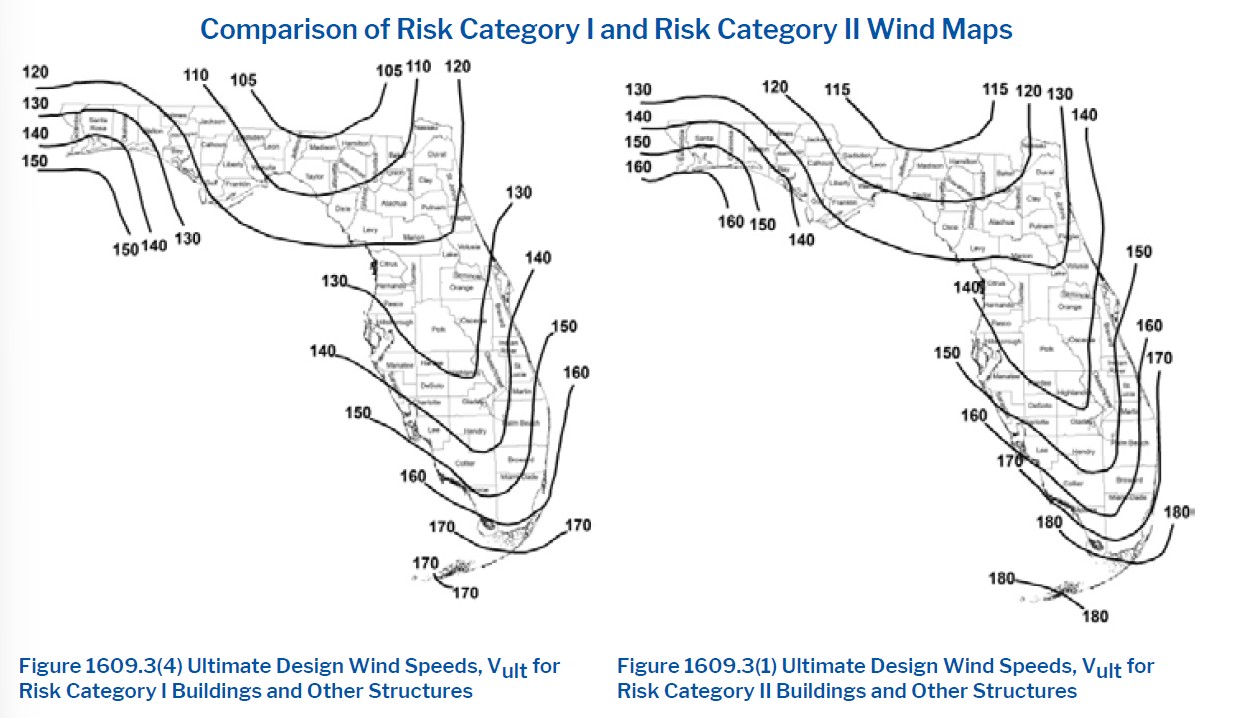

As the code sometimes does, a catch-all category is created for when factors that determine the other categories don't apply. In this case, it determines that if a building isn’t category I, III or IV, then by default it is category II, which is the most common risk category. For years, it has been a common perception that many code requirements do not apply to risk category I structures and, in a few cases, that is true. Specifically, the structural design requirements for risk category I are less stringent, particularly for resistance to wind loads. This is accomplished in the code through the ASCE 7 standard: its wind maps reduce the category I wind speed contours in most cases by 10 mph compared to risk category II. This can be seen below when you compare the category I (left map) and II (right map) wind speed maps from FBCB.

It is clear from the contours in the wind speed maps that structural design requirements for risk category I structures are reduced (left map below). What about roof coverings and, more specifically, asphalt shingles? Are the requirements for shingles different based on risk category? Looking at the following code sections, the answer seems to be clear and contrary to a common misperception. (Appropriately, the FBC Residential subcode only includes a risk category II map because the residential subcode only applies to that risk category. So, for our investigation, we will refer to the Building subcode not the Residential subcode.)

2023 Florida Building Code, Building, Eighth Edition

CHAPTER 3 USE AND OCCUPANCY CLASSIFICATION SECTION 301 SCOPE

301.1 General.

The provisions of this chapter shall control the classification of all buildings and structures as to occupancy and use. Different classifications of occupancy and use represent varying levels of hazard and risk to building occupants and adjacent properties.

CHAPTER 4 SPECIAL DETAILED REQUIREMENTS BASED ON OCCUPANCY AND USE

453.12 Roofing.

453.12.1 Class A materials.

All roofing materials shall be labeled Class A per ASTM E108 and shall be certified by a nationally recognized independent testing laboratory. All roofing systems shall be installed within the limitations of the test procedure for surfacing, deck cross slope, and combustibility.

Taken together, these sections don’t imply that all roofing materials must be Class A but they do provide requirements for roofing materials listed as Class A, which nearly all asphalt shingles are.

CHAPTER 15 ROOF ASSEMBLIES AND ROOFTOP STRUCTURES

SECTION 1507 REQUIREMENTS FOR ROOF COVERINGS

1507.2.5 Asphalt shingles.

Asphalt shingles shall have self-seal strips or be interlocking and comply with ASTM D3462.

1507.2.7.1 Wind resistance of asphalt shingles.

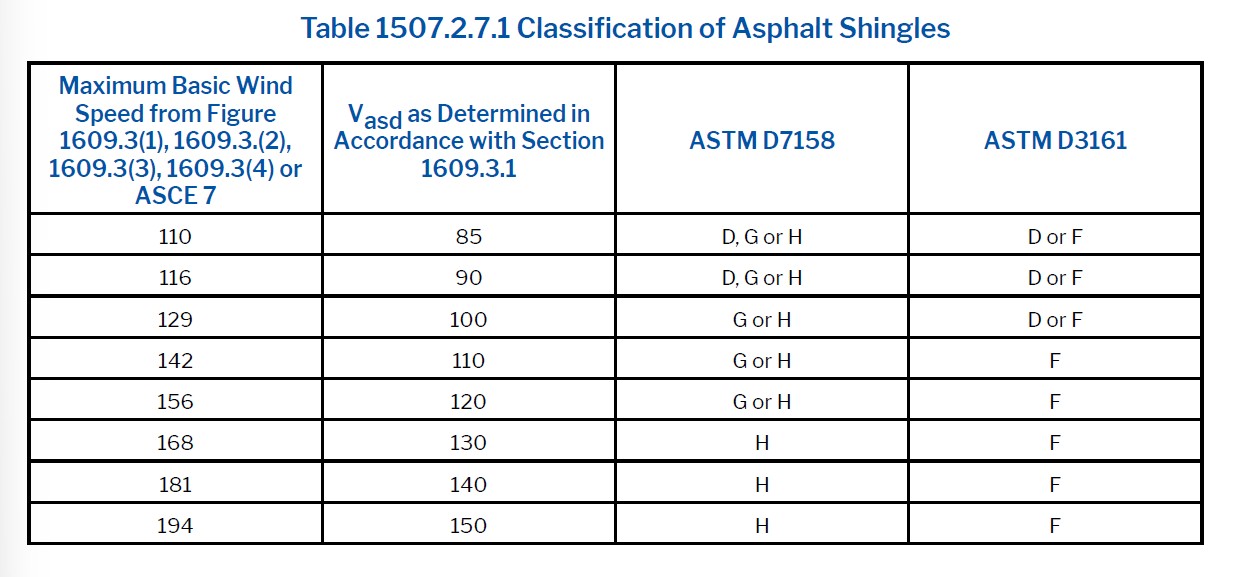

Asphalt shingles shall be tested and classified in accordance with ASTM D3161, ASTM D7158 or TAS 107. And shall meet the required classification in accordance with Table 1507.2.7.1 to resist the applicable wind speed per Figure 1609.3(1), 1609.3(2), 1609.3(3) or 1609.3(4) based on risk category. Asphalt shingle wrappers shall be labeled to indicate compliance with one of the required classifications, as shown in Table 1507.2.7.1.

Clearly, asphalt shingles used on risk category I structures (included above by reference to the 1609.3(4) wind speed map) must still comply with Table 1507.2.7.1 and be labeled accordingly on the wrapper. The code section above requires a label on shingle wrappers and specifies some of the information that the label must contain. The code definitions below expand on this requirement.

CHAPTER 2 DEFINITIONS

LABEL. An identification applied on a product by the manufacturer that contains the name of the manufacturer, the function and performance characteristics of the product or material and the name and identification of an approved agency, and that indicates that the representative sample of the product or material has been tested and evaluated by an approved agency (see Section 1703.5, “Manufacturer’s designation” and “Mark”).

LABELED. Equipment, materials or products to which has been affixed a label, seal, symbol or other identifying mark of a nationally recognized testing laboratory, approved agency or other organization concerned with product evaluation that maintains periodic inspection of the production of the above-labeled items and whose labeling indicates either that the equipment, material or product meets identified standards or has been tested and found suitable for a specified purpose.

MANUFACTURER’S DESIGNATION. An identification applied on a product by the manufacturer indicating that a product or material complies with a specified standard or set of rules (see “Label” and “Mark”). The code is clear that shingle wrappers require labels and on what information those labels must contain. Despite this, wrappers encountered in Florida, like the one on page 18, do not comply with these FBC requirements: other than a corporate name, this one label is all that the wrapper contains. Notably, the wrapper lacks any Table 1507.2.7.1 classification information.

With this information the question arises, “Why are these so-called B-grade products so pervasive in our market area?” The answer, I believe, has to do with how asphalt shingles are produced and, of course, economics. A shingle manufacturing line runs at 600 to 900 feet per minute. It is a very complex manufacturing process that produces several hundred shingles in less than a minute. Even when a manufacturing defect is caught almost immediately, hundreds of shingles may still contain the defect. These shingles can’t be sold with a warranty or as code compliant through testing. This isn’t a rare occurrence, so shingle manufacturers must deal with these seconds or B-grade shingles. Disposal is an option but comes with its own problems, so most manufacturers provide them to companies that often resell them as seconds. Some of these companies have built re -wrapping facilities near shingle manufacturing plants: that should give you an idea of how many shingles we are talking about. Undoubtedly, thousands of squares per month. One such company makes this statement in their advertising that I’ll paraphrase: B-Grade shingle roofing materials contain minor defects like color variations or aesthetic issues. They are ideal for budget-conscious buyers that aren’t looking for a warranty. They state that they can be used on sheds, barns or temporary installations.

So, where should these shingles be used? Based on the FBC requirements we have looked at, certainly not in Florida. I think from the building code information provided, you’ll agree that shingles without proper testing and labeling should not be shipped, distributed, sold or installed in Florida. When these subgrade shingles are readily available, the temptation to use them, even on occupied structures, and reap the financial benefit of doing so, is too great for some. If those who choose to use them are forced to remove and replace them for the original contracted price, they might feel differently.

FRM

Mike Silvers, CPRC is Owner of Silvers Systems Inc. and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.